MYOG

Annas backpacks – AK01 and AK02

Make your own back pack

Some years ago I visited my dear friend Kerstin and her boyfriend Thom in Bremen. They are both into hiking and also interested in hiking with as light a pack as possible. They have given me a lot of good advice and also been so kind and lent me their light tarp tent and their wood stove a couple of times.

During my visit they showed me their backpacks that they have made themselves, they were very tiny and very very light, I think they didn’t weigh more than 300 gr. That inspired me to make one for myself. I started to search on the net and found a lot of people who shared their experiences and knowledge in making their own gear. One site I can really recommend is Anders Jonssons, a Swedish guy who makes all his gear himself.

This inspired me to start sketching my first backpack and I used Anders backpack as a starting-point. I decided to make it a little bit bigger than Thom and Kerstins as I’m not that hard core yet. I found the materials at Shelby in Finland, I chose two kinds of fabric; one that was a little bit stronger and heavier for the back and bottom and one that was lighter and thinner but still quite strong. I also ordered buckles and webbings. I sew it during Christmas at my mothers place, who is a tailor and has a big cutting table and some nice sewing machines. I usually spend Christmas there making clothes so she is used to me taking over her sewing studio during the holiday.

It turned out to be really fun to make and not as hard as you might expect. A little tricky now and then as because I made the pattern myself, I didn’t have any real instructions. My goal was to make a back pack that weighed 500 gr and the end result was slightly higher 575 gr but I have to say I am really happy with the result.

My hiking friend Ýrr was jealous, so we decided to make a deal – a really good deal! She knitted me a really nice Icelandic sweater and I made her a backpack. And I have to say my second became even better then my first so I will soon start making myself a new one.

I have used the backpack on two longer hikes and one shorter. I have had to make some small repairs but never anything serious.

I can really recommend making your own backpack, unfortunately I do not have any proper pattern, further down you can see a sketch of my backpack pattern. You can find plenty on the net, for example at backpacking.net.

Icelandic wool sweaters

Icelandic wool sweaters are warm and comfortable. They are nice to wear in the evenings. The knitted pattern is typical, but I designed them as we wanted them practical for our hiking. Since I don’t like wool close to my face and neck I made a wide collar on my sweater, Anna wanted a collar to warm her neck and she wanted a zipper. The sweaters are tight, since we don’t want any extra weight. Here are some free patterns

Anna and I made a deal, she made me a backpack and I knitted her a sweater.

Tarptent making over Christmas (Anna)

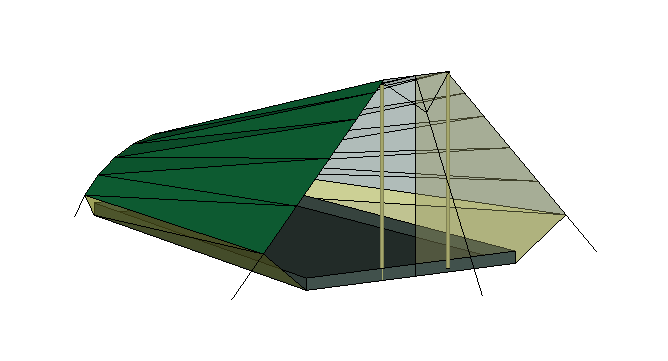

A sketch made in Sketch up.

During this years Christmas, while visiting my mother, I have finally taking up my tent project again. It has been berried three years now and I was surprised to find it all most ready and also on how well I seem to have made it. Why I didn’t finish it back then is something I don’t remember, maybe I lost my believes in succeed in my project. At the moment I have high believes that it will work out just fine.

The only reason I did not finish it now was that I missed out some things to construct the fastening device at the back of the tent. When this is ready I will test to set up the tent in the field. I need to have it up to do the last decisions about how to solve the closing of the opening in the front.

The tent is a variation of Henry Shires tarptent and I have used some of his original pattern and instructions but I adjust it a bit:

www.tarptent.com/projects/tarpdesign.html

It is actually not so difficult to make your own tent, but it can be a bit tricky to handle all this huge amount of fabric which also is very slippery. You will need some space, I am happy that my mother is a tailor so she has a big room and a big cutting table that I can use.

It is also good if you have the possibility to set up the tent inside while testing as when it still not ready it is also quite fragile so even a breath of wind can make damages.

The fabric I choose to use is a very light sil nylon bought from www.extremtextil.de , (I cant really recall the weight but I think it was something like 60-80 gr). As mosquito net I used a fabric that you can buy at IKEA called SARITA. I used this as I have found other peoples recommendations to use this fabric, it is very light and cheap :) For the floor I used a little more strong fabric than the sil nylon. I bought it from www.shelby.fi

The goal is that my tent will have a weight of 1 kilo with the sticks.

I have got many nice tips from many different sites on the internet by people sharing their experiences in making their own tents, Among those is www.andersj.se and also the forum on the Swedish site: utsidan.se

I will soon post some images of my tent project and also try to make a closer description on how I made it.

A short follow-up on my tarptent project

Last weekend me and Yrr joined Amit and Gunnel for a sawing session at Amits house in Hammenhög. Amit has a very big space, very suitable for a tarptent-project. It is so big that you easily can set the tent up indoors which is very good before you have all fixing/secure points ready, a wind can easily ruin your project.

Yrr started with her rain jacket. She has found such a nice and beautiful fabric for this and she will write a post about this soon.

The tent is all most ready, and I thought I would be finish it, at least so much that I could make a outdoor test. But the bow construction was more tricky than I had imagine and it was really important to get it right as the the tent would easily break if I made a bad solution.

The next step is to set the last fixing points and then when I can set it up I will find out a closing/opening construction. I would like to avoid zipper so I will probably use Velcro.

Yrr, Gunnel and I making one of the first set-up. I have to say it looks promising. (foto. Amit Sen)

Annas latest backpack: [AK05]

My latest backpack (AK05) differs a bit from my previous models. It is made of silnylon and for the back and bottom I have used a bit stronger material, normally used for tent floors etc. This is the same principal I have used before. I am very happy with it and think I have improved some things. What I like and what I think will work really good is the mesh pockets on the outside that can be used for wet or dirty clothes, tent or other things you want carry inside the pack. It will also be very useful for things you want to reach easily during the day like lunch, stove etc.

The top pocket and top closure also have much better fit and construction than before, a solution I am very happy with. I will soon take some better pictures on this and post here.

The pack is very light, about 330 gram., which is about 200 gr less than before.

I made this pack for my boyfriend and I am now planing to make my self a similar one to be used on my long-distance hike this summer. Just to be on the safe side as I will be using it for a long period I want to make it in a little stronger fabric than silnylon. I am plan to use Dyneema Ripstop, some part will probably be made with a little lighter fabric.

UL wallet

Today I (Anna) made myself an UL (ultralight) wallet. I am quite happy with the result, even though I could have sewn it a little bit nicer. The next one will be much nicer looking as I know how to make it now.

The weight is only really nice, only 4gr and can hold 1 credit-card, 1 identity-card and some money. I used red silnylon.